DIGITAL MANUFACTURING WEEK 2021

DMW 2021

Building the factory of the future

in Liverpool City Region

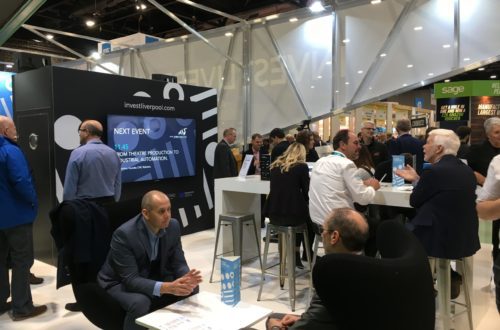

Join your peers at the industry’s biggest manufacturing show – Digital Manufacturing Week, here once again hosted in Liverpool from 8th– 12th November 2021. This year, it will be back to being an in-person event with all the Covid safety measures to make the event a great success.

Digital Manufacturing Week brings together expert speakers, industry-shaping influencers, delegates from the best manufacturers and the brightest emerging talent to help businesses at all stages of their Industry 4.0 development.

-

Witness game-changing technology

Witness game-changing technology -

Discover Liverpool City Region's exemplar digital manufacturing sector

Discover Liverpool City Region's exemplar digital manufacturing sector -

Attend The Manufacturing Leaders Summit

Attend The Manufacturing Leaders Summit

Produced by The Manufacturer magazine, the week-long event takes place at the city’s impressive arena and convention centre and encompasses Smart Factory Expo, Leader’s Summit, SME Growth Summit, The Manufacturer Top 100 Awards and the MX Awards. Organisers have taken all the necessary steps to ensure Covid measures are in place and these can be found HERE.

DISCOVER LIVERPOOL CITY REGION'S ADVANCED MANUFACTURING SECTOR

DIGITAL TRANSFORMATION SOLUTIONS THEATRE

The Invest Liverpool team will be hosting the Digital Transformation Solutions Theatre and will be on hand to deal with your enquiries within Smart Factory Expo – come and find us on Stand K51). Now in its sixth year, the Expo features nine content theatres and ten visitor zones focused on different digital manufacturing opportunities and featuring world-class presentations and exhibitors. Alongside this, we are running the Innovation Alley – a dedicated start-up corridor brimming with the Liverpool City Region’s entrepreneurial energy.

-

Visit Invest Liverpool at Digital Manufacturing Week 2021 on on Stand K51

Visit Invest Liverpool at Digital Manufacturing Week 2021 on on Stand K51 -

Smart Factory Expo returns live and in-person from Liverpool

Smart Factory Expo returns live and in-person from Liverpool -

Attend the Invest Liverpool Solutions Theatre

Attend the Invest Liverpool Solutions Theatre

THIS YEAR’S PROGRAMME

Our 2021 Digital Transformation solution theatre programme brings together the greatest minds and technology to demonstrate the revolutionary thinking behind Industry 4.0. As a City Region with an ambition that is matched by world leading infrastructure and dynamic talent to help you digitally transform your business, we will showcase the opportunities, capabilities and expertise we have to build your factory of the future. Our range of speakers will provide you with some of the latest thinking to help you make the strategic choices to execute transformation and change. Hear from businesses within the City Region who have transformed and those who are just starting their journey.

-

Invest Liverpool will once again host a lively and informative Solutions Theatre at Digital Manufacturing Week 2021

Invest Liverpool will once again host a lively and informative Solutions Theatre at Digital Manufacturing Week 2021

WHAT’S ON AT OUR DIGITAL TRANSFORMATIONS SOLUTION THEATRE LINE UP

THE VIRTUAL ENGINEERING CENTRE: How to introduce IoT Solutions to your business for enhanced productivity and improved connectivity across the factory floor.

10am – 10th November 2021

Thomas Kendall, IoT Specialist, Virtual Engineering Centre

Speaker: Thomas Kendall, IoT Specialist, Virtual Engineering Centre. Read more about Thomas Kendall on LinkedIn HERE.

What’s it all about?

IoT technologies can help to improve the type of data you collect, the speed in which this is collected and how it is presented to decision makers, enhance security of your working networks whilst utilizing cloud computing for enhanced remote working.

The Virtual Engineering Centre’s IoT Specialist will be discussing the ways in which your company can start to introduce IoT to your systems, improve connectivity and streamline processes for improved productivity.

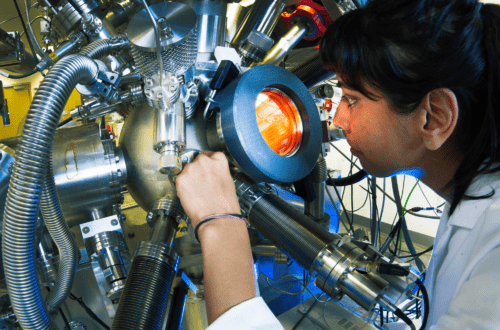

ADDITIVE MANUFACTURING FOR SMES – HOW CAN STFC HELP YOU?

12:30 – 10th November 2021

Georgina Leck, Business Development Manager, STFC

Michaela Kiernan, Business Development Manager, STFC

Speakers: Georgina Leck, Business Development Manager – STFC and Michaela Kiernan, Business Development Manager, STFC

What’s it all about?

Are you looking to adopt 3D printing technologies? Unsure where it can add value?

Join Georgina and Michaela from STFC who will discuss what you need to consider when integrating 3D printing into your business. No matter what industry, 3D printing could add value to your business through rapid prototyping, product performance, improving your supply chain, or the production of jigs and fixtures.

This talk will explain how SMEs can work alongside STFC’s additive manufacturing experts and utilise their latest 3D printing technologies. STFC have a wide range of capabilities, including metal printing and materials enforced with carbon fiber.

Learn how SMEs can access FREE support in the adoption of 3D printing technologies through funding programmes. STFC’s current funding programmes will be featured in this talk and details on how you can get involved. The talk will conclude with a case study from a company that STFC have supported through rapid prototyping.

Digital Transformation in Manufacturing – Develop digital capabilities to gain an edge in a hypercompetitive market.

1:30 – 10th November

Michael Darracott, Managing Director, MGISS

Speakers: Michael Darracott, Managing Director, MGISS (Mobile GIS Services). Read more about Michael on LinkedIn HERE.

What’s it all about?

Digital transformation in manufacturing involves integrating digital technologies into processes and products to increase manufacturing efficiency and quality. Digital transformation in manufacturing focuses on: Improving operational efficiency and reducing costs. It’s about technology, data, process, and organisational change.

Increasing competition in the manufacturing industry puts pressure on organisations to reduce costs, improve customer experience and increase profitability. Organisations armed with digital forces are disrupting business models with new value propositions. This disruption causes a challenge for manufacturing organisations but is also a chance to adopt digital themselves.

Leveraging Geospatial data and technology plays an increasingly important role in forecasting and scoping the future. The falling cost of data acquisition along with computing power for data processing and analysis is infinitely scalable even for the smallest organisations. Data technology can deliver significant business value within a few clicks of a mouse.

With a spotlight on digitalisation progress, businesses often base their decision-making on a combination of newly acquired, real time updated sensor data and poor-quality existing information. This is precarious when organisations hold large silos of legacy data residing in outdated systems and processes because the predominantly reactive nature of business operations is impacted by seemingly authoritative but poor-quality data.

More widely, the rise in urbanisation, population growth, climate change, ageing infrastructure and supply shortages are all combining to create a barrier to innovation. Geospatial data technology will enable businesses to step away from reactive, engineering-led solutions and move towards preventative and predictive solutions underpinned by data truth.

In addition, Sustainability takes centre stage. Sustainability is no longer an option -it’s an imperative. Awareness and alarm about the impact of human activity on the environment has begun to shift buying and investment behaviour around the world. Increasing energy use, resource depletion and waste generation are creating an urgency to rethink current consumer and business practices, and specifically to address priorities related to sustainability.

There are also some fundamental realisms that the manufacturing industry needs to face up to before it can extract value from geospatial data and move towards sustainable systems of asset insight to ultimately produce a framework for sustainable digital transformation

Factory Monitoring – Establishing a Game Plan for Digital Transformation

2:30 – 10th November 2021

Luke Walsh, Managing Director, Brainboxes

Speaker: Luke Walsh, Managing Director, Brainboxes. Read more about Luke Walsh on LinkedIn HERE.

What’s it all about:

An introduction to factory monitoring, how to self-assess your position, and what you need to know to get started. As we discuss integrating hardware and software, network essentials, data capture systems, and in-house development considerations, we’ll establish the next steps to secure success on your digital transformation journey.

PSW INTEGRITY – PRESENTATION, EXCELLENCE AND DELIVERY

3pm – 10th November 2021

Speaker: Ron McKay, Managing Director, PSW Integrity. Read more about Ron on LinkedIn HERE.

What’s it all about?

PSW Integrity is a body of knowledge and applied technologies which deliver, however, are not limited to, failure modes and effects analysis, facilitating and understanding human factors in reliability, planning and scheduling. We innovate to stay at the forefront of our industry through developing our services, investing in our people and technologies and collaborate on a global & local scale to continually challenge ourselves and expand our capabilities.

During the presentation you will discover more about PSW Integrity including:

- Our best-in-class reliability products and services to provide optimised asset management.

- How we endeavour to help reduce the carbon footprint of businesses

- Our ability to manage customers assets in the most effective, efficient and safe manner throughout the asset lifecycle.

- Condition Monitoring (CM) programs and surveys- Early detection of defects enables planning and drives a proactive maintenance culture and increased asset liability.

Bringing order to the chaos of traditional fermentation methods in kombucha through digital transformation processes

3:30 – 10th November

Sam Watson, MD and Fermenter, The Fermentation Station

Speaker: Sam Watson, MD and Fermenter, The Fermentation Station. For more information listen to a podcast from Sam and his Fermentation Station business partner, Amy Yarker, HERE.

What’s it all about?

An introduction to TFS and the fermentation process in kombucha, the challenges faced by small brewers using traditional methods, solution through digital transformation, collaboration with LCR holistic and PSW integrity and scaling up in the future.

Liverpool’s Industrial Digitalisation journey. A blueprint for local government and university support driven by SMEs

10am 11th November 2021

Andrew Borland, Head of Engineering at Virtual Engineering Centre

Speaker: Andrew Borland, Head of Engineering at Virtual Engineering Centre. Read more about Andre on LinkedIn, HERE.

What’s it all about?

Liverpool has led the UK in the development and delivery of locally focused innovation support programs aimed at benefiting SMEs. The City Region has faced many societal and economic challenges but is home to a solid bedrock of small manufacturing businesses that form essential link in the supply chain for sectors from aerospace and automotive to oil and gas and pharmaceuticals.

This presentation will focus on how business leaders, local government and universities came together to develop one of the most effective regional development interventions in the field. The LCR4.0 has been cited by BEIS and a national exemplar and by the Financial Times as a European leader in digital.

The discussion will set out how SMEs, government policy makers and industry bodies can go about developing their levelling up initiates tailored to their own regional needs.

Data collection and analysis for higher manufacturing outputs

10:30 – 11th November 2021

Cliff Brereton, CEO, DATAHONE Limited

Speaker: Cliff Brereton, CEO, DATAHONE Limited. Read more about Cliff on LinkedIn, HERE.

What’s it all about?

How data is collected and the importance of IoT devices and software interfaces. Statistical and AI modelling, where and why it is used. The session will look at current the landscape in terms of digitalisation of the shop floor environment including:

- Why digitalisation and particularly data capture and analysis drives bottom line increases.

- Why throughputs, yields and uptime can never be optimal without better ‘situation awareness’.

- Why with increasing energy and raw materials costs, being more efficient on the shop floor is critical to maintaining margins.

- The strategic value of accurate and timely data when making capital purchasing decisions

- DATAHONE ‘Intelligent Factory’ – Why our R&D base in Liverpool is important to us, especially in relation to our local partners in the LCR4.0 Holistic program and their technology demonstrators.

AUGMENTED REALITY, NOVELTY, CREATIVITY AND MEANINGFUL CHANGE

1:30 – 11th November

Alastair Eilbeck, Director, Meyouandus

Speaker: Alastair Eilbeck, Director, Meyouandus. Read more about Alastair on LinkedIn HERE.

What’s it all about?

Meyouandus are firmly rooted in the creative technology arts. And at first, glance this small creative studio does not seem a great fit for a smart manufacturing expo. However the technical experience and insights we have developed in our creative augmented reality and geo-locative work is increasingly seeing crossover into the commercial world. The core principles of AR – the ability to understand 3d space through a 2d camera, harness the IMU and GPS of mobile devices and use of 3d CAD and CGI assets, are standard components of many manufacturing and supply chain processes.

From applying AR and storytelling to improve the experience of passengers on intercity trains to looking at how a national retailer can harness its existing CAD, planogram, stock control and data processes to power new AR functions both internally and for its customers. In this presentation, we hope to make you consider whether you already have the underlying technical framework to support the meaningful use of AR in your business.

Soft leadership to encourage autonomy and creativity in engineers

2:30 – 11th November

Madina Barker, Director/Owner CNC Robotics

Speaker: Madina Barker, Director/Owner CNC Robotics

What’s it all about?

Much of the attention on leadership and management skills in SMEs has been on those possessed by the companies founders and Directors. This is essential but there is more to a business that its directors and the heart of any organisation is its team. Soft skills are important for leadership at all levels across the business to encourage autonomy and creativity.

The Increasing Uses of RFID Technology within Manufacturing

3pm – 11th November

Eric Jones, Managing Director – RFIDiom Ltd

Speaker: Eric Jones, Managing Director – RFIDiom Ltd

What’s it all about?

Eric will discuss the different RFID technologies that are available in the market today and how they can be used in manufacturing to serve business objectives such as effective inventory management, stock control, and facilitating just in time production and supply chains.

Eric will also highlight some of the projects that RFIDiom have undertaken in the manufacturing sector in the past. Some of these case studies include clients in the manufacturing sector who have used bespoke RFID solutions to ensure their products are tracked from creation in their assembly lines to the goods in at their customers’ premises; creating paperless lab production systems, and effective stock rotation in the manufacturing of perishable goods.

To join Invest Liverpool at Digital Manufacturing Week please click the button below.